The Foundation of Durability: Mastering Metal Surface Protection

In today's demanding industrial and commercial landscapes, the longevity and performance of metal components are paramount. Exposure to harsh environmental elements, corrosive agents, and constant wear can significantly compromise structural integrity and aesthetic appeal. A truly superior metal surface finish is not merely an enhancement; it is a fundamental requirement for ensuring the sustained functionality and operational reliability of critical assets across various sectors. This foundational aspect of material science directly impacts how well a product withstands the test of time and usage.

Achieving this level of resilience often hinges on selecting the right application method. Traditional painting techniques, while offering some protection, frequently fall short in terms of durability and resistance to chipping, scratching, and fading. This is where advanced solutions like powder coating emerge as the preferred choice. It delivers a robust, uniform, and aesthetically pleasing protective finish that significantly extends the lifespan of metal parts, making them suitable for even the most challenging conditions. The inherent qualities of powder coating provide a distinct advantage over conventional liquid applications.

The benefits of a high-quality surface treatment extend far beyond basic protection. It contributes to operational efficiency by reducing the need for frequent maintenance and replacement, thereby optimizing resource allocation. For components subjected to heavy use or extreme weather, a meticulously applied coating acts as an impenetrable shield, preserving the underlying material. This proactive approach to preservation is crucial for maintaining the integrity of everything from architectural structures to intricate machinery, ensuring peak performance and prolonged service life.

Specialized expertise is indispensable for unlocking the full potential of this technology. A dedicated powder coating shop possesses the specialized equipment, skilled technicians, and comprehensive understanding required to execute an impeccable finish. Such facilities are adept at handling diverse projects, offering tailored solutions for every need. Whether it's a large-scale industrial component or a delicate artistic piece, a professional establishment can provide a custom metal coating that meets precise specifications, guaranteeing exceptional results.

The meticulous application process involved in powder coating ensures a consistent and even layer, free from drips or runs often associated with liquid paints. This uniformity is key to its superior protective qualities and aesthetic appeal. Furthermore, the wide array of available finishes, textures, and colors allows for both functional enhancement and significant design flexibility. This versatility makes it an invaluable solution for industries prioritizing both endurance and visual excellence, ensuring that products not only perform well but also look exceptional.

Where Superior Metal Finishes Make a Difference

- Automotive Components: Provides exceptional resistance to road salts, UV radiation, and abrasions, significantly extending the life of wheels, chassis parts, and engine components. This contributes to vehicle longevity and maintains aesthetic appeal, even under rigorous daily use.

- Architectural Elements: Enhances the durability and visual appeal of railings, window frames, and outdoor furniture. The durable powder paint protects against weathering, fading, and corrosion, ensuring structures remain aesthetically pleasing and structurally sound for decades.

- Industrial Machinery: Offers robust defense against chemicals, impacts, and extreme temperatures, crucial for equipment operating in demanding environments. A precise color coating helps in identification and safety, while also preventing wear and tear on critical parts.

The Science Behind Unyielding Protection

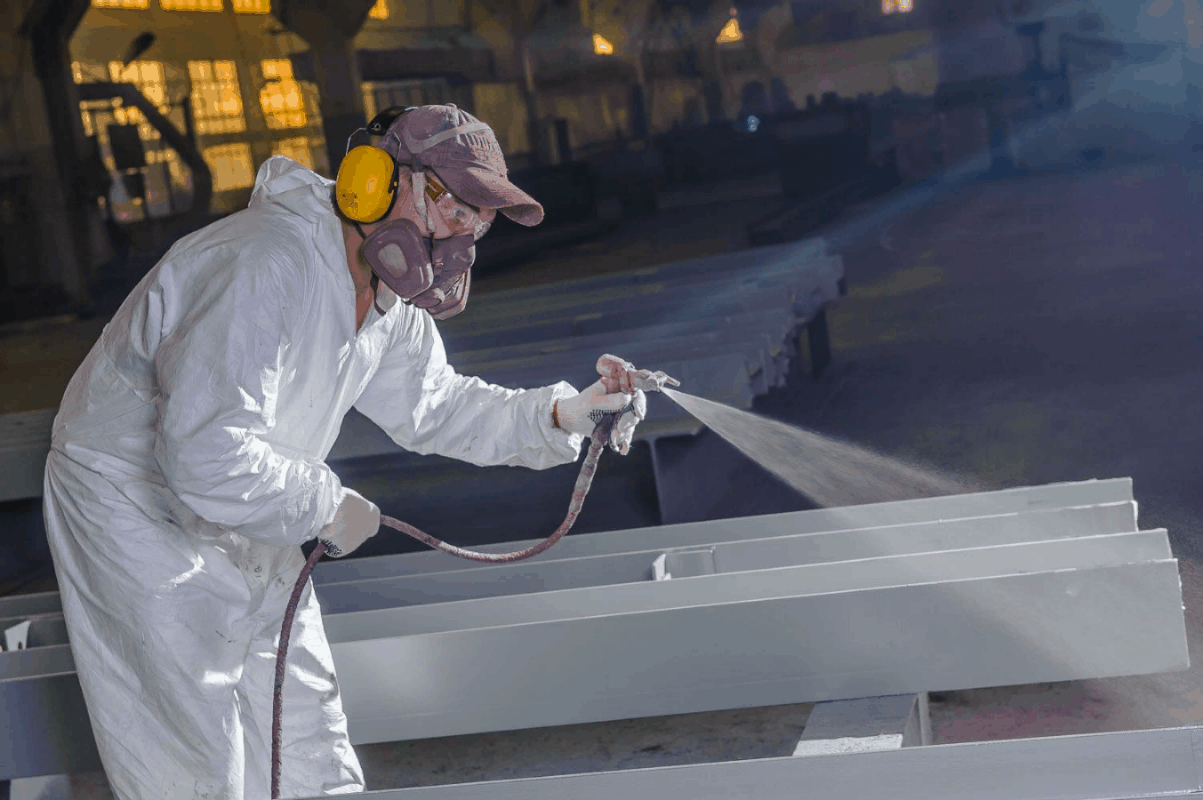

The journey to an ultimate protective finish begins long before the application of any material. Surface preparation is arguably the most critical stage of the entire industrial coating process. Experts universally agree that proper cleaning and profiling of the metal substrate are non-negotiable. This typically involves processes like abrasive blasting to remove rust, scale, and previous coatings, followed by thorough degreasing and chemical treatments. A pristine, properly etched surface ensures optimal adhesion, preventing premature flaking or delamination of the subsequent coating layer, which is vital for lasting performance.

Once the surface is prepared, the application of powder itself is a sophisticated technique. Electrostatic charges play a pivotal role, attracting the finely ground powder particles to the grounded metal object. This method ensures a remarkably even and comprehensive coverage, even on complex geometries. Following application, the coated item enters a curing oven where the powder melts and then chemically cross-links, forming a continuous, solid film. This thermal bonding process is what gives powder coating its characteristic toughness, flexibility, and superior resistance to physical and chemical damage, setting it apart as a truly professional coating.

The diversity of powder formulations available today allows for highly specialized applications. For instance, epoxy powders are renowned for their exceptional hardness and chemical resistance, making them ideal for industrial equipment. Polyester powders, on the other hand, offer excellent UV stability and weatherability, making them perfect for outdoor architectural elements. Urethane powders combine flexibility with abrasion resistance, suitable for high-traffic areas. Understanding these distinctions and selecting the appropriate type, along with various powder color options, is crucial for achieving the desired performance characteristics and aesthetic outcome for each unique project.

While traditional liquid paints have their place, the advantages of powder coating in terms of environmental impact and performance are increasingly recognized. Liquid paints often contain volatile organic compounds (VOCs), which are harmful to the environment and human health. Powder coating, being a dry process, eliminates VOC emissions, making it a more eco-friendly choice. Furthermore, the overspray can be collected and reused, leading to minimal material waste. This combination of superior durability, broad application versatility, and environmental responsibility positions powder coating as a leading solution for modern metal protection needs.

Ensuring Lasting Quality and Performance

The pursuit of an ultimate protective finish is a commitment to quality and longevity. By understanding the intricate processes and selecting the right partners, businesses and individuals can ensure their metal assets are equipped to withstand the most challenging conditions. This approach not only safeguards material integrity but also contributes to greater operational stability and reduced long-term maintenance needs, ensuring that components perform reliably for years to come.

Partnering with an experienced and reputable local coating company like Mountain Powder Coating is key to realizing these benefits. Their expertise in material science, application techniques, and quality control ensures that every project, regardless of its scale or complexity, receives a finish that not only meets but often exceeds industry standards. Such a collaboration guarantees that your metal components receive the highest level of care and protection available, solidifying their durability.

Ultimately, investing in a superior metal surface finish is a strategic decision that underpins the enduring performance and aesthetic excellence of any metal product. It reflects a dedication to quality and a forward-thinking approach to asset preservation, ensuring sustained reliability and visual appeal in any environment.

leave a comment