The integrity and aesthetic appeal of metal components are paramount across countless industries, from automotive to architectural design. Ensuring their longevity and resistance to environmental stressors requires more than just basic protection; it demands a sophisticated approach. Traditional methods often fall short in delivering the enduring quality and precise finish modern applications necessitate, leading to premature wear and diminished visual appeal.

This is where advanced solutions like powder coating emerge as the superior choice. Unlike liquid paints, powder coating offers a robust, uniform, and environmentally conscious alternative. Our state-of-the-art powder coating shop is equipped to handle a diverse range of projects, providing a durable and aesthetically pleasing finish that stands the test of time and harsh conditions, ensuring your components look better for longer.

The true value lies in the ability to provide custom metal coating services. Every project has unique requirements, whether it's specific color matching, texture preferences, or enhanced resistance to chemicals or abrasion. Tailoring the coating process ensures that each item receives the optimal treatment, perfectly aligning with its intended function and desired appearance, making it truly unique.

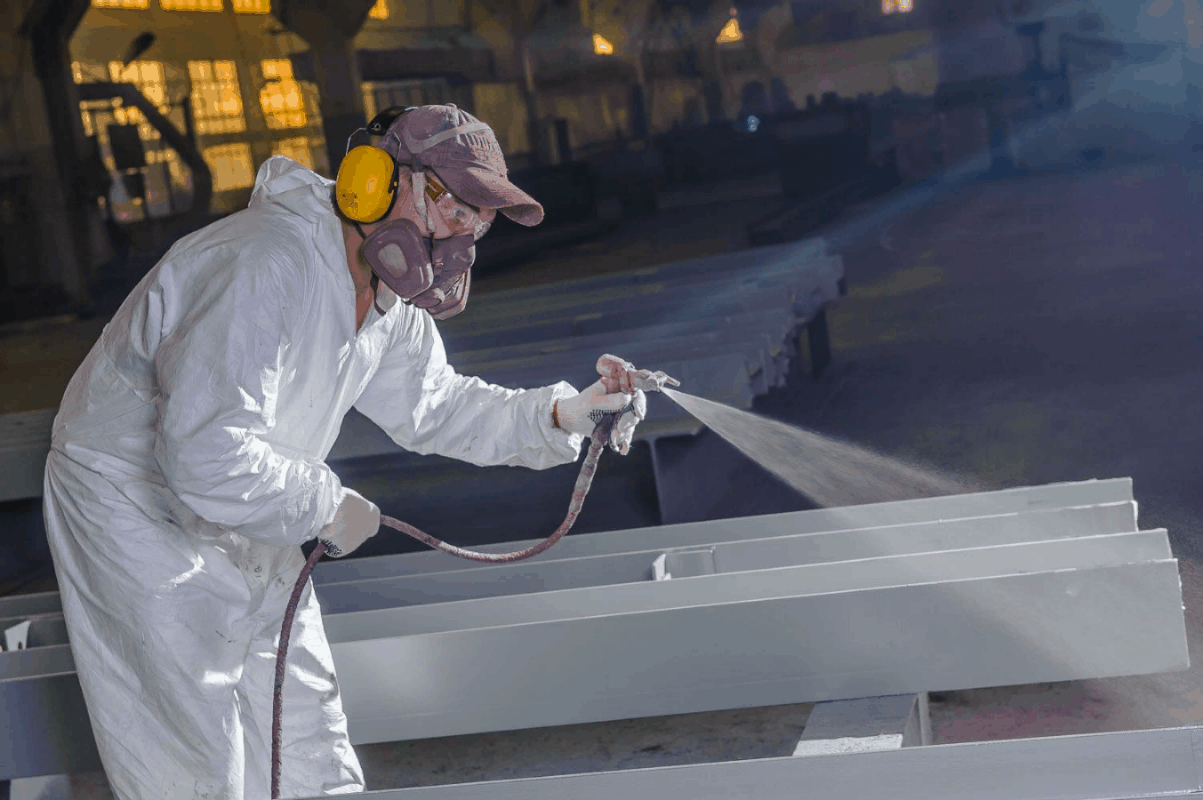

Achieving a truly exceptional protective finish demands not only advanced technology but also profound expertise. Our team comprises highly skilled professionals who understand the nuances of various metal substrates and coating materials. This combination of cutting-edge equipment and seasoned knowledge guarantees a consistent, high-quality application every single time, preventing common issues like uneven coverage or premature peeling.

The industrial coating process we employ utilizes finely ground particles of pigment and resin, which are electrostatically charged and sprayed onto the electrically grounded object. This method ensures maximum adhesion and a remarkably uniform layer, resulting in a finish that is significantly more resistant to chipping, scratching, and fading than conventional paint, ensuring lasting performance in demanding environments.

This commitment to excellence extends beyond mere durability. We understand that the visual aspect is just as critical. A superior coating enhances the overall perception of quality and design, contributing significantly to a product's market appeal and user satisfaction. It's about combining ultimate protection with impeccable style, making items not just functional but also visually striking and desirable.

Key Applications and Advantages of Powder Coating

- Automotive Components: Provides superior resistance to road debris, chemicals, and UV exposure, extending vehicle part lifespan and maintaining aesthetic appeal for years.

- Architectural Elements: Offers exceptional weatherproofing and a wide array of powder color options, enabling creative freedom while protecting structures from the elements.

- Industrial Machinery: Delivers robust corrosion and abrasion resistance, crucial for operational longevity and reducing maintenance needs in demanding manufacturing environments.

The Science Behind Superior Metal Protection

The technical superiority of powder coating stems from its unique application and curing process. The electrostatic charge ensures even coverage, even on complex geometries, while the heat-curing phase creates a molecular bond that is inherently more flexible and durable than air-dried liquid paints. This results in a thicker, more uniform coating without drips or sags, providing a flawless surface.

Expert opinions consistently highlight powder coating's environmental advantages. With zero volatile organic compounds (VOCs) and minimal hazardous waste, it represents a significantly greener alternative to traditional liquid painting. This not only aligns with modern sustainability goals but also creates a safer working environment within our local coating company facility, benefiting both staff and the planet.

Achieving an optimal metal surface finish is inextricably linked to meticulous surface preparation. Any contaminants, rust, or old coatings must be completely removed before powder application. Industry experts emphasize that without proper cleaning and pretreatment, even the most advanced durable powder paint will fail to adhere correctly, compromising the coating's integrity and longevity.

The versatility in aesthetics is another key point. Beyond basic protection, powder color options are virtually limitless, allowing for precise brand matching or unique design statements. Specialized finishes, such as textured, matte, gloss, or metallic effects, provide unparalleled design flexibility, making it a preferred choice for designers and engineers seeking specific visual outcomes that truly stand out.

While the benefits are clear, the quality of the professional coating largely depends on the expertise of the application team and the sophistication of the equipment. Inexperienced application can lead to issues like "orange peel" texture or inconsistent thickness. Therefore, choosing a reputable powder coating shop like Mountain Powder Coating ensures adherence to the highest industry standards, guaranteeing a flawless result.

Conclusion: Investing in Lasting Quality

In summary, advanced metal coating offers an unparalleled combination of durability, aesthetic versatility, and environmental responsibility, making it the ideal choice for a wide range of applications requiring superior protection and finish.

By choosing a specialized provider, clients ensure their components receive a superior color coating that not only protects but also enhances their value and extends their service life, minimizing the need for frequent replacements or touch-ups.

Mountain Powder Coating is dedicated to delivering exceptional custom metal coating solutions, leveraging expertise and cutting-edge technology to meet the most demanding specifications and exceed client expectations for quality and performance.

leave a comment