The Science Behind Superior Surface Protection

In today's demanding industrial landscape, the longevity and aesthetic appeal of components are paramount. A robust surface treatment is essential, extending operational life and ensuring resilience against harsh conditions. This understanding forms the bedrock of modern manufacturing and asset preservation strategies across many sectors, from automotive to construction.

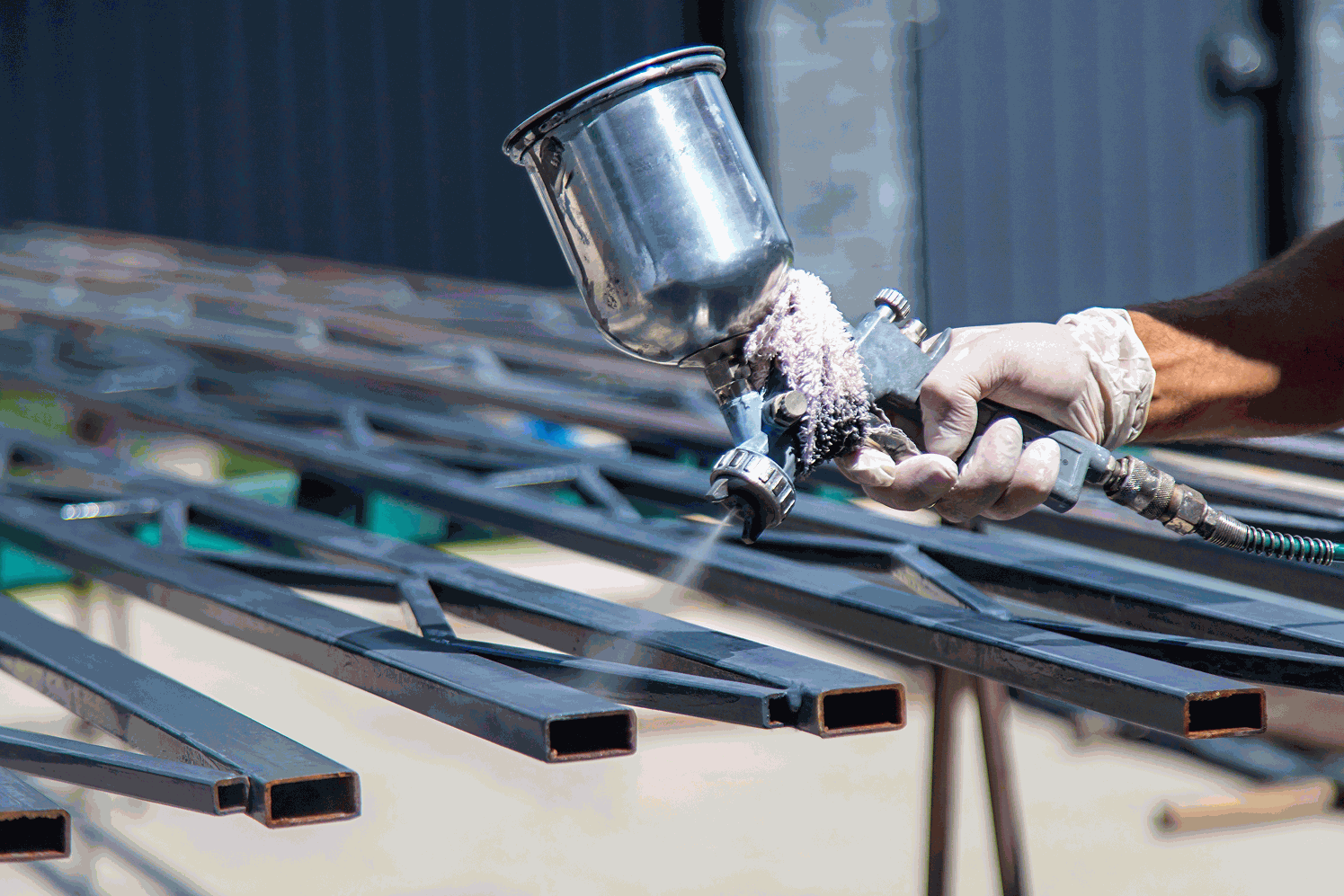

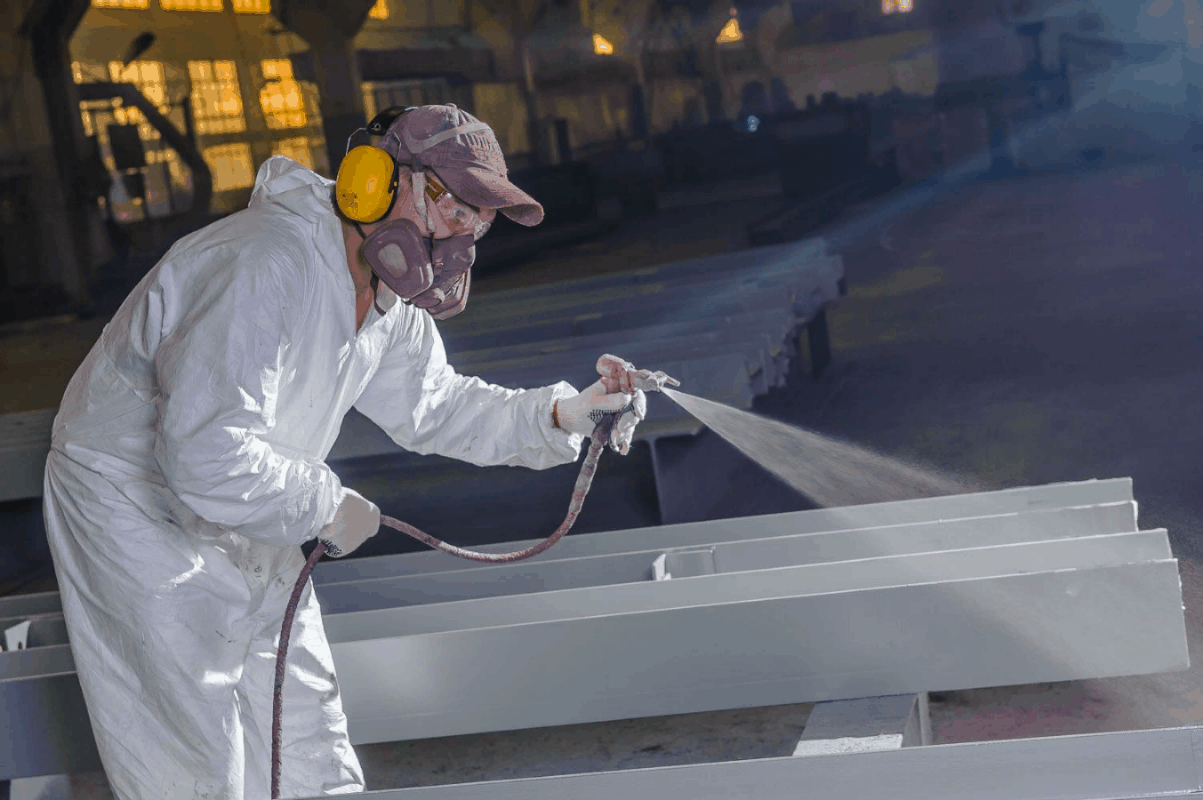

Among various finishing techniques, the industrial coating process utilizing powder paint stands out as a superior method. It offers unparalleled durability, aesthetic flexibility, and environmental responsibility. Applied as a dry powder and cured under heat, it forms a hard, protective layer. This distinct mechanism contributes to its exceptional performance, making it a preferred choice for many demanding applications.

The journey from a raw metal surface to a resilient product involves critical, meticulously controlled stages. Precision at every step is essential for optimal adhesion and performance. A well-executed coating not only enhances visual appeal but also provides a formidable barrier against corrosion, abrasion, and chemical exposure, crucial for any component's longevity.

Choosing the appropriate coating solution requires deep understanding of material properties, environmental stressors, and functional requirements of the end product. This tailored approach ensures maximum protection and performance, optimizing asset lifespan. It's not a one-size-fits-all solution but a carefully considered application of specialized knowledge.

At the heart of delivering high-quality finishes is a dedicated powder coating shop equipped with advanced technology and skilled personnel. These specialized facilities handle diverse materials and part sizes, ensuring consistent, high-quality results. Expertise within such a shop is vital for navigating different powders and techniques, delivering a superior protective finish.

Commitment to excellence in applying durable powder paint reflects a broader dedication to quality and sustainability. Powder coating minimizes volatile organic compounds (VOCs) during application, making it an eco-friendly choice. This blend of performance and responsibility solidifies its position as a leading solution for modern industrial finishing requirements.

Key Applications and Advantages

- Automotive Components: Provides exceptional resistance to chipping, fading, and corrosion for wheels, chassis parts, and engine components, extending their lifespan in harsh road conditions.

- Architectural Elements: Ideal for outdoor structures, railings, and window frames, offering a weather-resistant and aesthetically pleasing color coating that maintains its vibrancy for years.

- Industrial Machinery: Essential for heavy equipment and tools, delivering a tough, abrasion-resistant surface that protects against wear and tear in demanding operational environments.

Expert Perspectives on Coating Excellence

The effectiveness of the industrial coating process is often debated among material scientists and engineers, particularly concerning optimal preparation methods. Some experts emphasize thorough pre-treatment, including multi-stage cleaning and phosphating, arguing it forms the crucial foundation for adhesion. They contend that any compromise in this initial phase leads to premature coating failure.

Conversely, other specialists highlight advancements in powder formulations themselves. They suggest modern powders can exhibit greater tolerance to minor surface imperfections. While not advocating for negligence, they argue that overly complex pre-treatment might sometimes be overkill, focusing on innovative polymer chemistry and additives for a resilient metal surface finish.

A central point of agreement, however, revolves around the critical role of the curing process. Inadequate curing can severely undermine the coating's physical properties, leading to softness, poor adhesion, and reduced chemical resistance. Experts universally stress precise temperature and time parameters within the curing oven. Deviations compromise the integrity of the custom metal coating.

The choice of application method also sparks discussion. Electrostatic spray remains the industry standard, but advancements in tribo-charging and dense phase application systems offer alternatives with specific advantages. A reputable professional coating provider, like Mountain Powder Coating, understands these nuances, employing the technique best suited for each unique project.

Furthermore, the debate extends to quality control measures. While visual inspection is standard, advanced techniques like adhesion testing, impact resistance, and salt spray testing provide quantifiable data on coating performance. There's a strong consensus that comprehensive testing is indispensable for verifying that the applied coating meets all specified performance criteria.

Enhancing Longevity and Aesthetics

The precise industrial coating process, using durable powder paint, is crucial for superior component protection. It ensures both enhanced aesthetics and exceptional longevity, vital for asset integrity against environmental challenges.

Partnering with a professional provider, such as Mountain Powder Coating, guarantees specialized knowledge and diverse powder color options. This expertise delivers a robust finish, extending component lifespan and ensuring sustained performance.

Ultimately, understanding this intricate process empowers informed decisions. It leads to resilient products that offer lasting protection and significant long-term value.

leave a comment