Metal items form the backbone of countless industries and daily applications, from intricate machinery components to architectural structures and consumer goods. Their inherent strength and versatility are undeniable, yet they are constantly exposed to a myriad of environmental stressors. Moisture, UV radiation, chemicals, and physical abrasion relentlessly attack metal surfaces, leading to corrosion, fading, and structural weakening over time. Without adequate protection, the operational integrity and aesthetic appeal of these vital assets can rapidly diminish, leading to frequent maintenance or premature replacement.

The degradation of metal surfaces is not merely a cosmetic issue; it profoundly impacts functionality and operational longevity. A corroded part can fail unexpectedly, causing disruptions in production or compromising safety. Faded or chipped surfaces detract from the overall quality perception of a product or structure. Understanding these challenges highlights the critical need for advanced preservation strategies that go beyond basic upkeep. It underscores why a robust defense against environmental wear is not just beneficial, but absolutely essential for sustaining the performance and appearance of metal items.

This is where the significance of professional coating truly emerges. It represents a sophisticated approach to safeguarding metal assets, offering a resilient barrier against the elements. Unlike conventional paints, modern coating technologies, particularly those applied by a dedicated powder coating shop, provide superior adhesion, enhanced durability, and a consistent finish. This specialized application creates a shield that dramatically extends the service life of metal components, preserving their structural integrity and visual appeal for years to come. It’s a proactive measure that mitigates future issues.

Choosing a professional coating is about more than just applying a layer of color; it's about enhancing the fundamental characteristics of the metal itself. A high-quality protective finish can significantly improve resistance to chipping, scratching, and fading, ensuring that items retain their original condition even under demanding circumstances. This meticulous process transforms ordinary metal into something far more resilient, capable of withstanding the rigors of its operational environment. It's a testament to the fact that careful surface treatment can unlock new levels of performance and endurance.

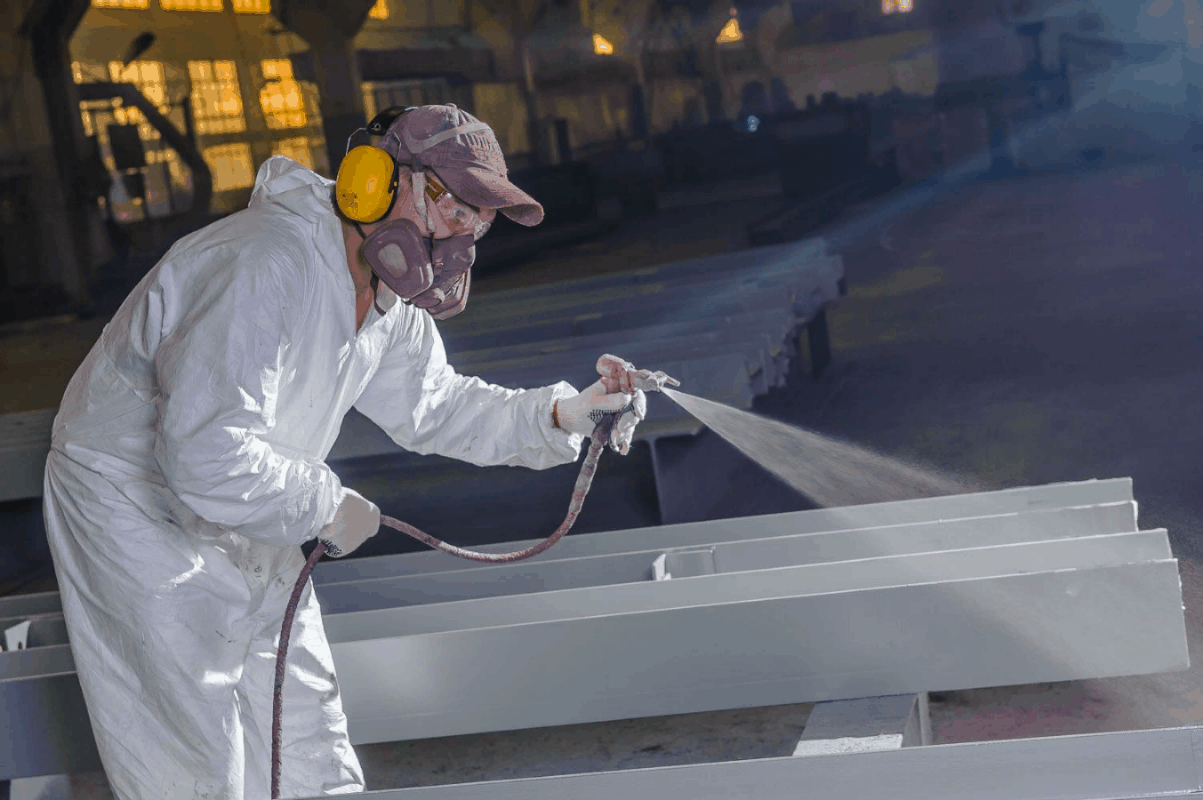

The expertise involved in applying such finishes is paramount. It requires precise preparation, specialized equipment, and a deep understanding of material science. Every step, from surface cleaning to curing, plays a crucial role in the final outcome. A well-executed coating job provides not only an aesthetic upgrade but also a profound functional enhancement, making metal items more robust and reliable. It’s a commitment to excellence that ensures the longevity and continued utility of valuable metal assets in various settings.

Ultimately, investing in a superior protective finish is a strategic decision that supports the enduring performance of metal components. It secures their operational readiness and maintains their visual standards, ensuring they continue to serve their intended purpose effectively. For those seeking reliable solutions, engaging with a reputable powder coating shop like Mountain Powder Coating ensures access to expert application and a commitment to quality that stands the test of time, delivering consistent and exceptional results for every project.

Applications and Advantages of Advanced Coatings

- Industrial Machinery Components: Provides enhanced resistance to chemical exposure, abrasion, and extreme temperatures. This ensures machinery operates reliably for longer periods, reducing the frequency of replacements and maintaining operational continuity.

- Automotive and Motorcycle Parts: Offers superior defense against road salt, moisture, and UV damage, preserving both the structural integrity and aesthetic appeal. Custom metal coating allows for personalized looks with exceptional durability.

- Architectural and Outdoor Elements: Delivers long-lasting beauty and weather resilience for railings, gates, and fixtures. A professional coating prevents rust and fading, ensuring structures maintain their pristine appearance through varying climates.

Expert Insights on Coating Technologies

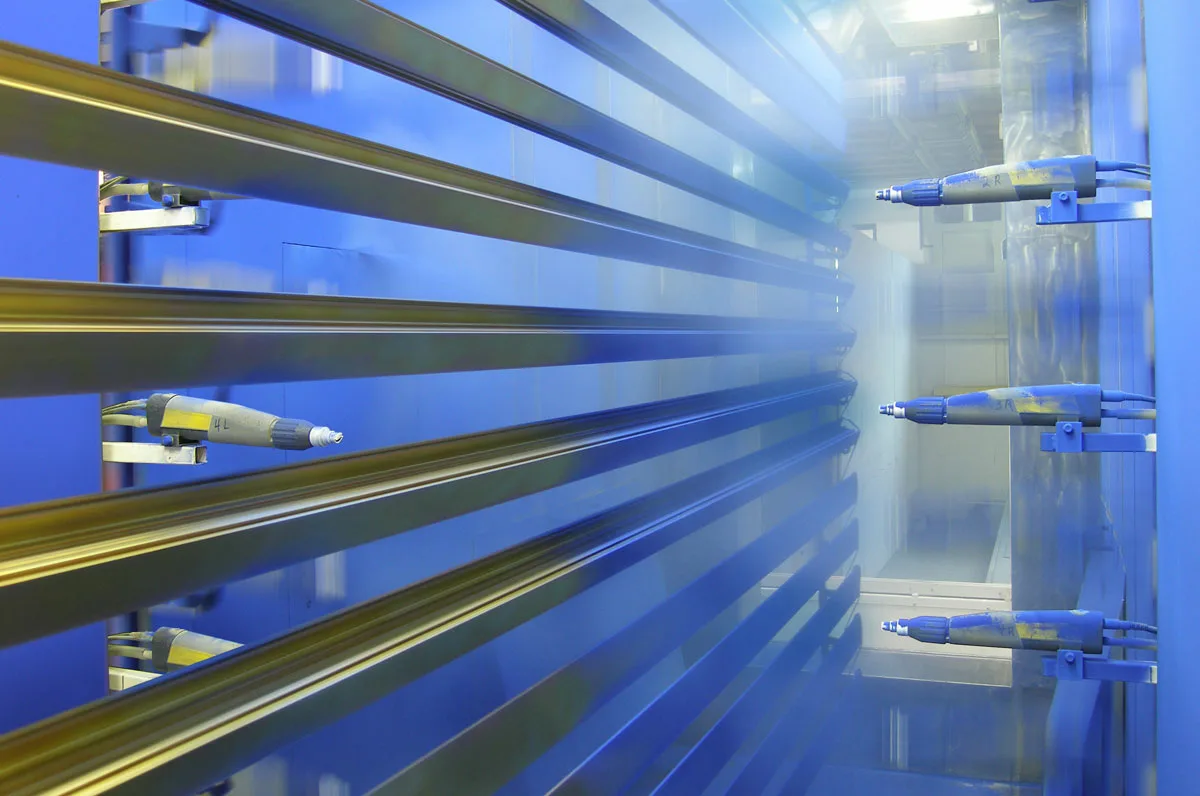

The evolution of the industrial coating process has brought forth remarkable advancements, with powder coating standing out as a premier method for metal protection. Experts widely acknowledge its superiority over traditional liquid paints in several key areas. The dry application process means zero volatile organic compounds (VOCs) are released, making it a more environmentally conscious choice. Furthermore, the robust nature of durable powder paint ensures a thicker, more uniform coating that is inherently more resistant to chipping, scratching, and fading, which are common weaknesses in conventional liquid applications.

A significant advantage of modern coating techniques lies in their ability to offer extensive customization. With a vast array of powder color options, clients can achieve specific aesthetic goals while simultaneously benefiting from superior protection. This flexibility extends to custom metal coating solutions, where specific textures, gloss levels, and even metallic effects can be achieved. This bespoke approach ensures that whether the need is for a vibrant consumer product or a subtle, high-performance industrial part, the finish perfectly matches both functional requirements and design aspirations, elevating the overall quality.

The success of any professional coating hinges critically on meticulous surface preparation. Industry specialists consistently emphasize that even the most advanced coating material will underperform if the substrate is not properly cleaned and pre-treated. This crucial initial phase removes contaminants, rust, and old finishes, creating an optimal surface for adhesion. A properly prepared metal surface finish ensures that the powder coating bonds effectively, maximizing its protective qualities and ensuring its longevity. Neglecting this step can lead to premature flaking or bubbling, undermining the entire application.

The choice of a qualified local coating company is paramount for achieving optimal results. Professional application by skilled technicians ensures that every stage of the industrial coating process is executed with precision. From selecting the appropriate powder to controlling the curing temperature, expertise makes a tangible difference in the final product's quality and durability. Companies like Mountain Powder Coating possess the necessary equipment, experience, and commitment to deliver a metal surface finish that not only looks exceptional but also provides lasting protection against the most challenging conditions, securing the longevity of your assets.

Ensuring Lasting Protection and Visual Appeal

The enduring quality of metal items is not left to chance; it is actively shaped by the protective measures we apply. Professional coating stands as a testament to this principle, offering a comprehensive solution that extends beyond mere aesthetics. It's about preserving the integrity and operational readiness of valuable assets, ensuring they perform reliably and maintain their appearance over an extended period. This proactive approach significantly reduces the need for frequent repairs or replacements, contributing to sustained functionality.

Ultimately, the decision to opt for a professional coating is a strategic one, focused on safeguarding the operational life and visual standards of metal components. It’s a commitment to quality that ensures metal items are not only visually appealing but also robustly protected against the elements and daily wear. By choosing an expert application, you are securing the long-term viability and performance of your metal assets, allowing them to withstand the test of time with grace and strength.

leave a comment