OUR SERVICE

- Expert powder coating for steel, aluminum, and various metals. Durable, beautiful finishes with advanced curing for lasting protection.

- Thorough surface preparation: cleaning, degreasing, phosphating, or sandblasting for superior coating adhesion and longevity.

- Custom metal fabrication from concept to completion. Precision-engineered structures and parts, expertly finished with powder coating.

- Precision color matching using RAL & NCS. We create unique custom hues to perfectly meet your project's aesthetic vision.

- Restore your items! Old coating removal, surface renewal, and fresh powder application to revive looks and protection.

- Secure delivery of your finished products. Expert packaging ensures safe transit, protecting your coating from any damage.

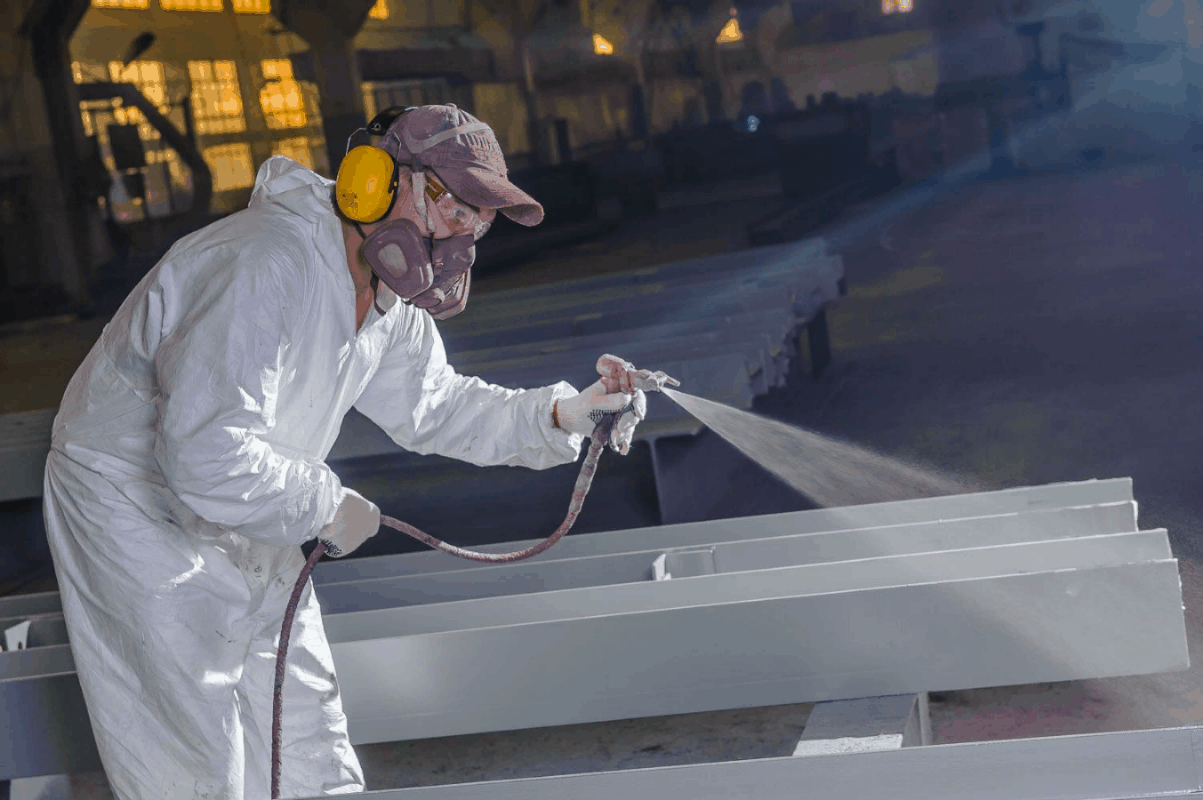

The Foundation of Flawless Finishes: Our Meticulous Surface Preparation

At Mountain Powder Coating, we believe that the true measure of a superior coating lies in its foundation. As a premier powder coating shop and a trusted local coating company, our unwavering commitment to meticulous surface preparation ensures every project achieves a truly enduring and aesthetically pleasing finish. We understand that a high-quality professional coating begins long before the first application of color.

Precision Cleaning & Degreasing

This fundamental first step is paramount. We employ advanced cleaning and degreasing techniques to thoroughly strip away all surface impurities, including oils, greases, dirt, dust, and any residual contaminants. Our specialized solutions penetrate and lift even stubborn residues, leaving the metal surface impeccably clean and perfectly receptive. This critical process ensures that the subsequent coating can form an optimal bond, setting the stage for a flawless metal surface finish.

- Removes all organic and inorganic contaminants.

- Prepares the surface for maximum adhesion.

- Essential for preventing common coating failures.

Advanced Phosphating Treatment

For applications demanding exceptional adhesion and enhanced corrosion resistance, our phosphating service is indispensable. This sophisticated chemical conversion process creates a microscopic, crystalline phosphate layer directly on the metal surface. This inert layer acts as an outstanding anchor profile, significantly boosting the mechanical and chemical bond of the applied durable powder paint. It's a vital component of our comprehensive industrial coating process, providing an additional barrier against environmental elements and extending the lifespan of the coated item.

- Creates an ideal surface for superior coating adhesion.

- Enhances corrosion protection significantly.

- Suitable for a wide range of ferrous metals.

Abrasive Blasting (Sandblasting)

When a more aggressive and transformative surface preparation is required, our abrasive blasting service, commonly known as sandblasting, delivers unparalleled results. This mechanical process propels abrasive media at high velocity, effectively removing rust, mill scale, old paint, and other stubborn surface imperfections. It simultaneously creates a consistent, textured profile on the metal, which is absolutely crucial for the optimal mechanical interlocking of a custom metal coating. This ensures that whether you choose a vibrant color coating from our extensive powder color options or a subtle protective layer, it will adhere with maximum strength and longevity.

- Removes rust, scale, and previous coatings.

- Creates an optimal surface profile for mechanical adhesion.

- Prepares even heavily corroded or uneven surfaces.

At Mountain Powder Coating, every item entrusted to us undergoes a carefully selected and executed preparation regimen. This meticulous approach guarantees that your components receive a robust protective finish, engineered to perform exceptionally and retain its aesthetic integrity for years to come.